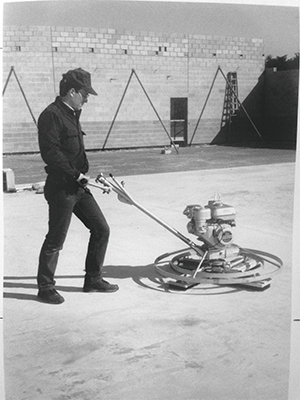

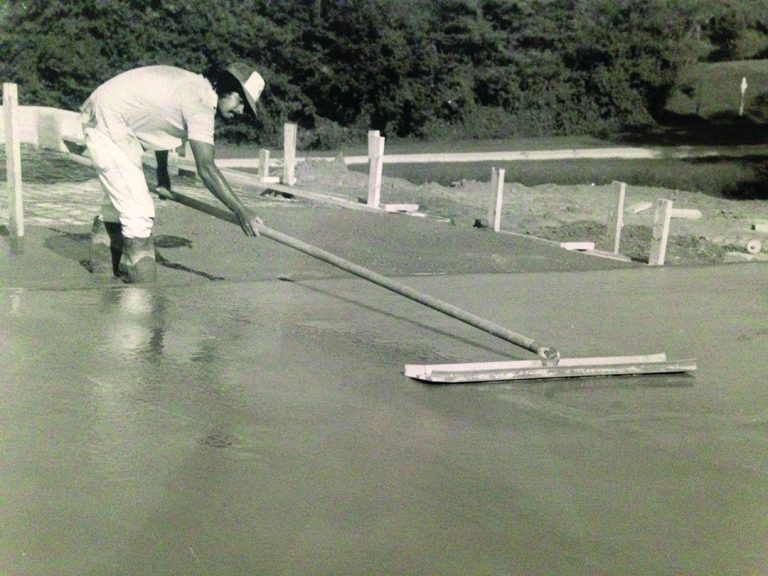

Since 1963, Wagman Metal Products, Inc. has been a leading supplier of power trowel replacement blades and floating pans in the concrete industry.

We thank our distributors and customers for their continued support.

About Us:

Now that Wagman Metal has passed the fifty year mark, we’re constantly striving to keep things fresh and new. We’ve been a leading supplier of power trowel replacement blades for over fifty two years, and thanks to my wonderful group of co-workers we’re still at the top of the heap. Through hard work and constant attention to detail, my staff has managed to keep our loyal customer base supplied in a timely fashion with the quality concrete finishing products they have come to know and trust. I know founders George Wagman Sr. and Jr. would be proud.

My own experience started at WMP, back in 1980, and the years have taught me well. What this means for you, is an owner who is hands on and dedicated to bringing you the best quality finishing products at competitive prices with reliable service and inventory. After all, it’s got my name on it. I will always stand behind the products we sell, I guarantee it!

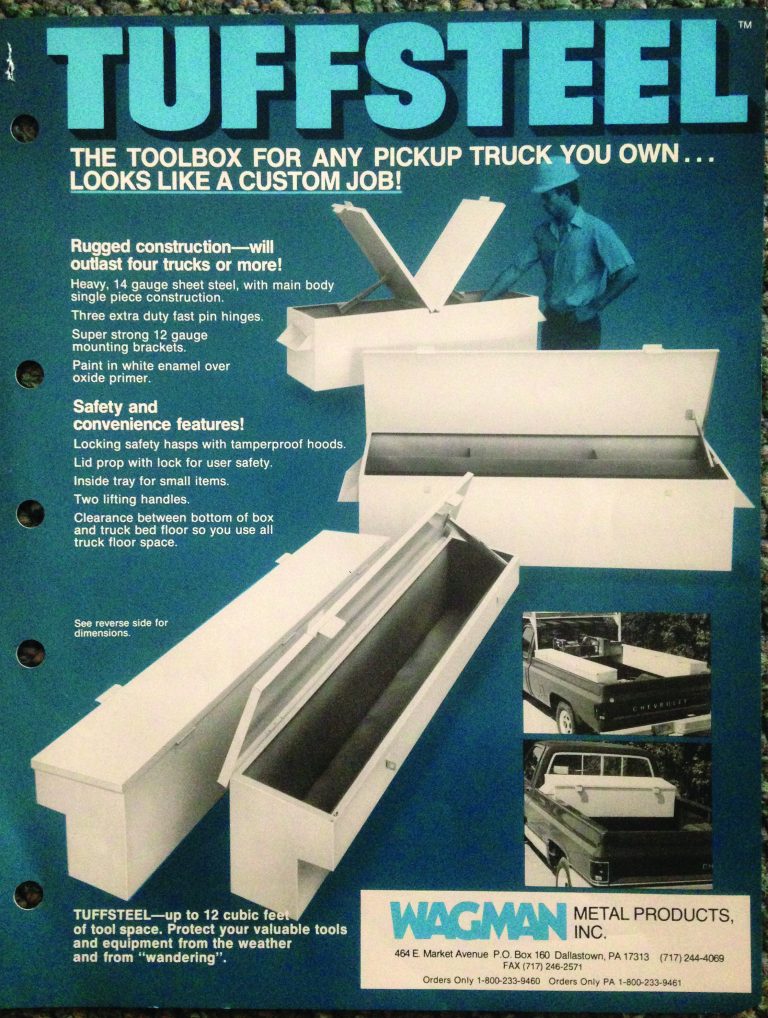

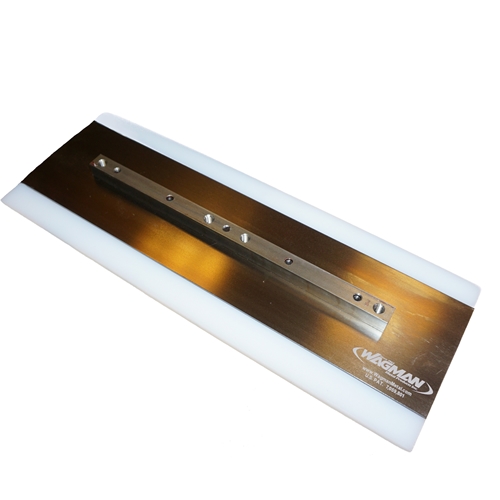

Looking back reveals the innovation and ingenuity this company has brought to the flatwork industry. Wagman has lead the way over the years with new products like the Gold Pro Blade, the Blue XL Blade, and the entire line of Poly Pro Blades. When the ride-on power trowel first started becoming popular, Wagman was one of the leaders to offer float pans – the highly popular Pro Float Pan.

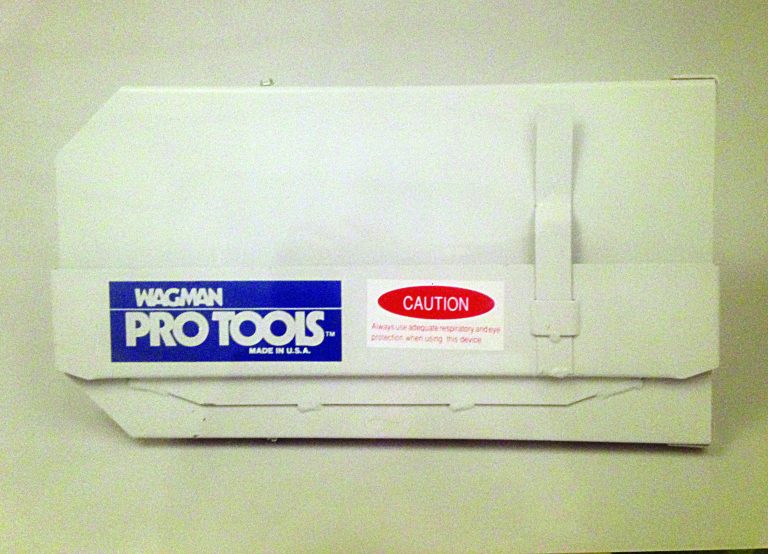

Our Pro Tool line has been a hallmark of ingenuity and alternative design from its earliest days. Ideas like T-slots and curved high screed walls have pioneered bull floats, hand floats, and our unique speed float. Our new line of hand trowels offers the hand finisher some of the highest quality tools at extremely competitive prices.

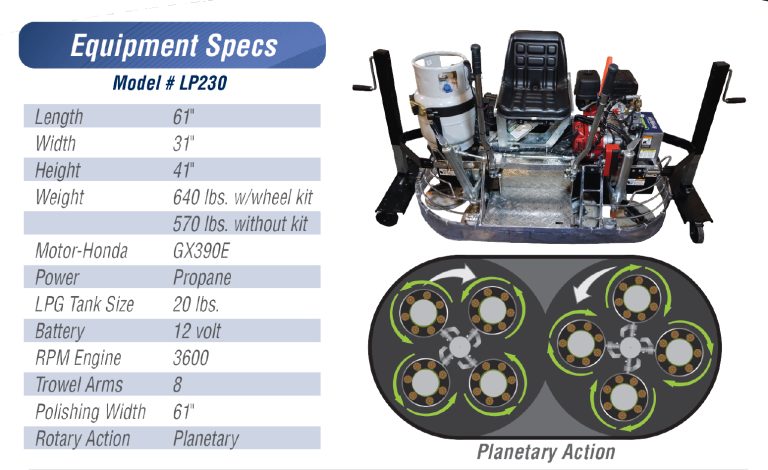

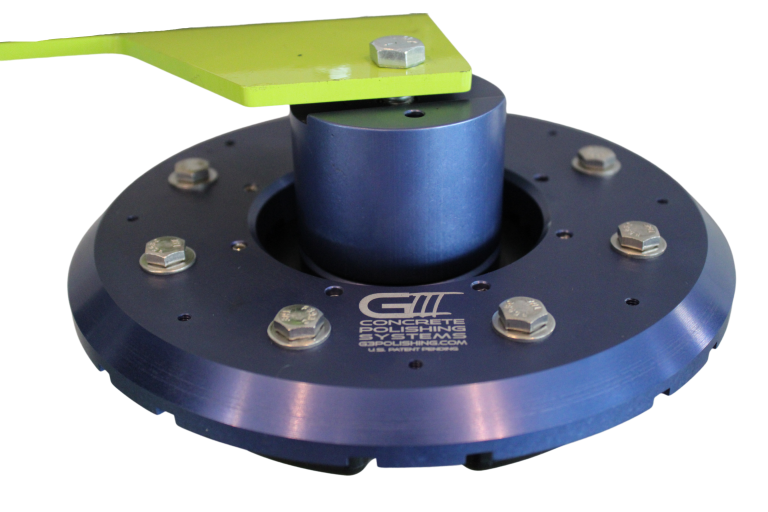

More recently we’ve pioneered the use of the power trowel for alternative uses. Our development of the Revolution Rotary System, has spawned a new era in trowel based floor clean up tools.

This development has also lead to our exciting new line of diamond polishing tools all run from your power trowel. The GHP System ushers in a new era in low cost diamond grind, hone, and polish capabilities.

Of course, I’d be remiss if I didn’t finish with a nod to our Eco friendly chemical products that will help save you time and money. Eco Coat and Eco Crete are designed to be your environmentally friendly partners in keeping your equipment clean, your forms from sticking and your clean-up chores easy.

George F Wagman III President, Wagman Metal Products, Inc.

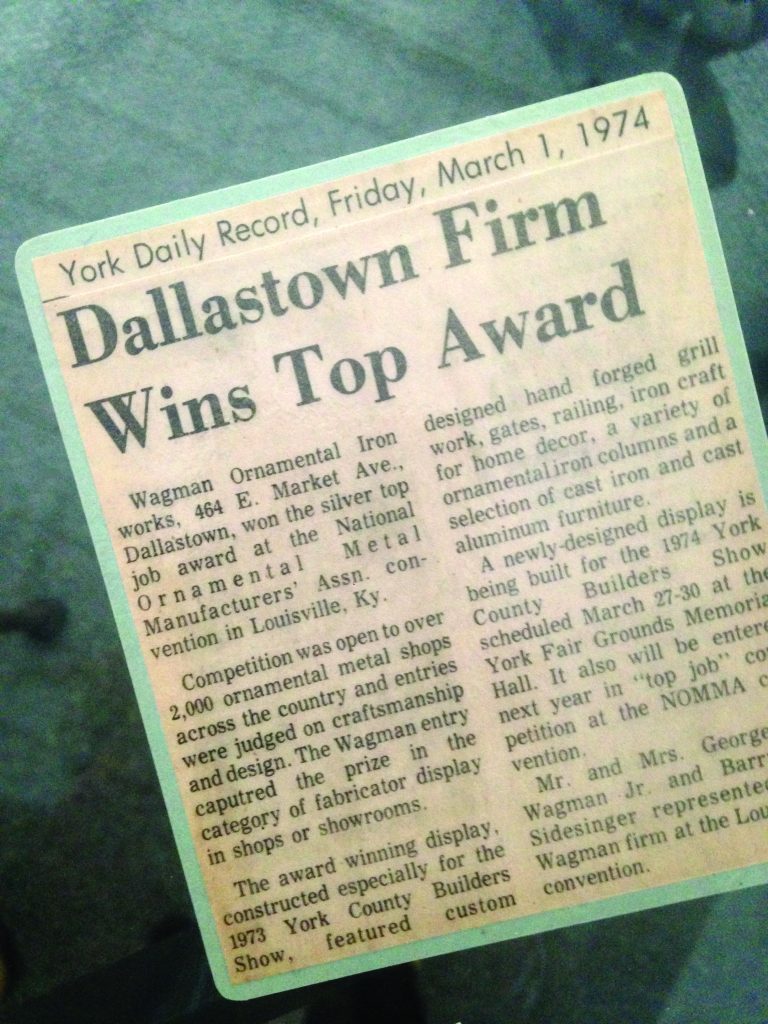

The History Of Wagman Metal Products, Inc.

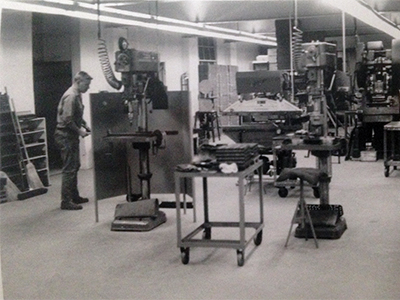

How It All Started

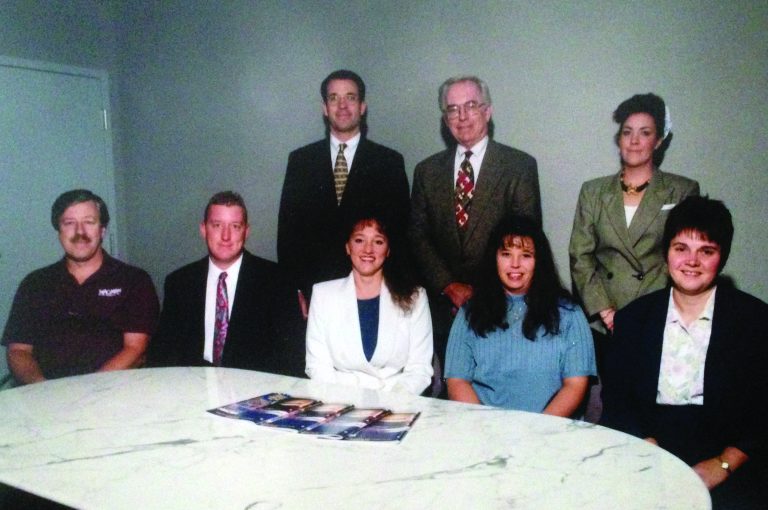

Our Leadership Team

George Wagman III

President, CEO

George was born and raised in York, PA, and grew up working for Wagman Metal Products, Inc. George has always had a strong work ethic, and a fascination with things mechanical. George has two sons, George IV 26, and Nicholas, 24, both mechanically gifted individuals of whom he is extremely proud.

George started at Wagman Metal in 1979, and in 1995 his late father George F. Wagman Jr. promoted George to the position of president of Wagman Metal Products, Inc. and since then George has led the company to become the largest manufacturer of power trowel replacement blades, floating pans, and power trowel based concrete floor polishing systems in North America.

Wagman Metal Products is his life’s work, and George is proud of the innovation Wagman has pioneered in our industry. George is also extremely delighted with Wagman's sixty-person team, striving every day to make and keep this a world class manufacturing business.

Eric Nelson

Executive Vice President

Eric joined Wagman Metal Products, Inc. in Jan 2019 after spending most of his career in the power transmission industry. He was born and raised in Lancaster County and is married with two children and seven grandchildren.

He received an undergraduate degree and master’s degree from Penn State University.

On the weekends he spends his time on the Chesapeake Bay boating and fishing with his family and friends.

Kevin Wilkie

Controller

Kevin joined Wagman Metal Products, Inc. in March 2019 following a career in public accounting, consulting and various accounting and finance positions for various manufacturing companies. He currently resides in Lancaster County and is married with two children and one grandchild. He graduated with an accounting degree from Elizabethtown College.